Mineral Core Information

Mineral Door Core products are manufactured using a low density mineral, man-made unique amalgam of diatomaceous earth, fiberglass, recycled newspaper, and other ingredients, that are capable of providing for exceptional fire resistant properties. The products offered are designed specifically for use in the manufacture of high performance fire resistant doors and doorsets. Due to the exceptional reliability and predictability of mineral Door Core product under fire test conditions, these materials have become a preferred base product for the fire testing of door related components where longer duration performance fire ratings are required. Configured with high density stile and rail layout with a sub faces of either MDF or Plywood. The products are configured for both 90 and 120 minutes performance.

Configurations

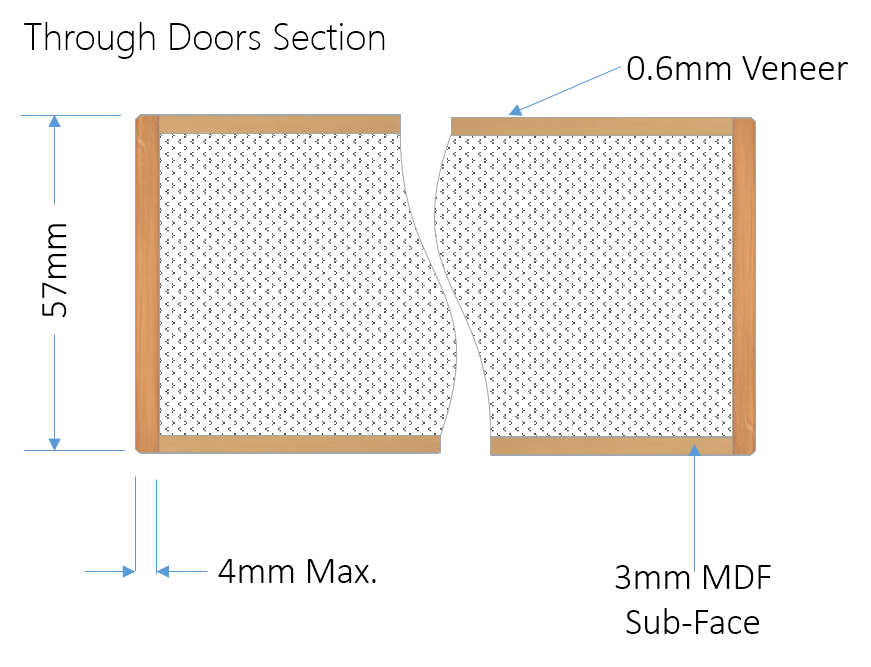

The core material is banded by Principal doorsets on all edges using high density mineral stiles and rails. The resultant blanks are then faced and edge lipped to provide for wood appearance finishes, PVC wrapped, Laminated, Fully Painted or primed ready for site finishing. The high density mineral is also used as the base material for the manufacture of frames that can be faced to match door leaves for doorsets requiring up to two hour minimum fire performance.

Extensive testing has also been carried out to provide users of mineral Door Core products sound attenuating performance options.

Further

Testing has been carried out in accordance with BS EN 1634-1 in anticipation of a requirement to satisfy this specification in due course. Due to the exceptional reliability and predictability of mineral Door Core product under fire test conditions, these materials have become a preferred base product for the fire testing where high performance fire ratings are required. Mineral Door Core products can be worked using standard woodworking tools.