Process roadmap (click to link to section)

Introduction to Management of your Projects.

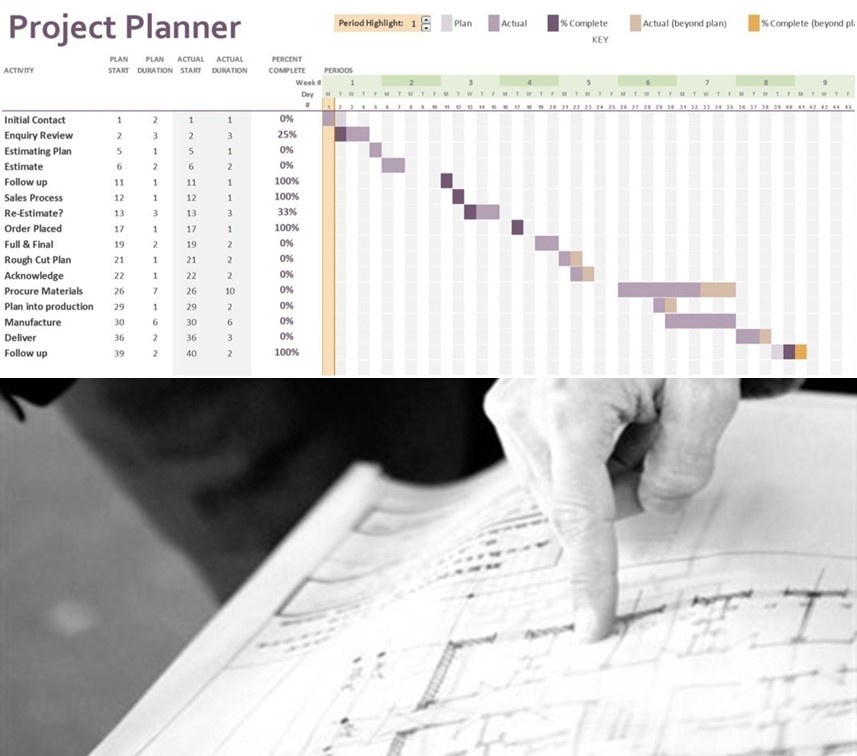

With projects of all shapes and sizes we developed our business systems, procurement and manufacturing to be agile and responsive whilst maintaining ability to scale. We have dealt with large projects over multiple phases as well as smaller single delivery projects.

With your complete satisfaction as our goal, we employ a proven systematic method of cost control that stems from initial enquiry to order all the way through every stage of the supply process.

At Principal Doorsets we seek to be transparent. As our valued customer, we offer as much of a complete door set "cartridge" as possible. One where you are fully aware of cost, unlike others, we seek not to impress with the lowest price due to fundamental materials missing or not pre-hanging our sets. We seek to offer you a doorset that requires fixing to your opening, nothing more to do. So if you would like us to offer you less (no hinge recessing, locks, left "in the white"), please make that clear and we will be happy to estimate your project.

Our process provides the following advantages:

- Accurate Estimates

- Highest Standards of Materials & Vendors

- Assistance and clarity

- Green and sustainable standards, practices and technologies

- Quality Assurance

- Management Information

- Accurate delivery information

- Customer Service

Enquiry Received

Our process begins with a careful evaluation of each project, examining performance, volume, finishes & program requirements:

There are two main options for making an enquiry with Principal Doorsets. You can call us; we will be delighted to talk through your project and advise you accordingly. Alternatively, you are welcome to send your architectural drawings, sketches, photographic references or schedules to us by email or post, in which case we will acknowledge receipt of them immediately, advising you who your client handler is and aim to return a free, comprehensive quotation within 14 working days.

At scope gathering, we try ensure that we get the specifications, performance requirements, finishes and items required. We review the performance criteria required which could include: fire, dimensional requirements, acoustic and sector specific needs (health, education, leisure etc.), duties (this includes traffic, anti-vandal, edge and face protection needs etc.) finishes, Ironmongery and joinery.

This stage includes understanding the architects concepts, delivery programme, completion date. All have a n effect on the cost build up with the more we understand of the project the closer we will control cost.

- Requirement Analysis

- Return Planning

- Project Delivery Schedule

Estimation

Closer evaluation to match performance requirements with project aspirations:

Ideally we will be working to your general layout drawings, specifications (L10, L20 & M40), elevation drawings, bill of quantities, schedules and other project briefing documents. We will review the performance requirements against the dimensions and product finishes ensuring that certification requirements are covered should they be required and products are within our portfolio of capability. Costing out the requirements and obtaining specialist materials along with any adverse lead times to generate an estimate and return back to you via email.

- Full understanding of project

- Availability & Costing of materials

- Compilation of Estimate

Sales

Our follow up of estimation ensures receipt and detail tailored to requirements, any changes or updates made here:

Consultation all the way - As things develop we are here to help and ensure you get the product that is right for your project. All our products are made individually (made-to-order) to suit your requirements, therefore to ensure we fully understand your project, we will be only too happy to visit you and discuss the vast options we have to offer you. Our visit may come before or after an order is placed, or we may visit on more than one occasion as required to cover all the details.

Depending on how your project is being managed, we will gladly deal directly with the architect, developer, project manager, contractor, interior designer or any other party involved.

- Ensure understanding

- Complete Value Engineering

- Win order, full & final, RFI's

Planning & Scheduling

Log order and plan into systems, RFI's, schedule line items validating all performance and compliance criteria, generate work instruction:

Our Project detailing team will spend a great deal of time and effort ensuring that every single detail of your requirements are captured, to reach a point where you are happy to sign off your order as final. This all important stage means that the order is ready to go into manufacturing, and we will be able to advise you of your expected delivery date; typical production lead time from sign off is 3 weeks although this can vary with demand or material availability.

NOTE: The lead time quoted to you at time of order only commences once sign off has been received on both the Order Acknowledgement and Order Confirmation documents.

Your chosen materials, ironmongery and options will all begin to come together in the hands of our skilled craftspeople and our industry leading machinery within our state-of-the-art facilities, through the various stages of manufacture, paint application, glazing and assembly until your products are ready for their final inspection and packaging for transport.

You are very welcome to visit our facilities by appointment at any stage during consultation or even to see your actual items being manufactured.

- Procure Materials

- Validate requirements

- Create works instruction

Manufacture & Delivery

Receive materials, release to manufacture and complete products ensuring rigorous quality controls followed, dispatch goods:

We specialise in timber door products; timber stands as the only truly green material with the huge advantage that it can be naturally replaced. Principal Doorsets are hugely committed to sustainable sourcing, with all timber being FSC® certified. Chain of Custody is available on request at no extra cost to you.

We work to the stringent terms and standards required by BS EN ISO9001 and Q-Mark.

Our products are made from timbers and engineered timber; a technically advanced approach to the use of wood in modern day applications. Lamels are laid with the grain in opposing directions to allow the timber to move whilst being countered by the grain of neighbouring sections, creating an exceptionally strong, rigid material that is then overlaid with a sub-facing material that enhances fire, anti-vandal and acoustic performance. The timbers we opt to use for our ranges are: Hardwood timber - choices, Softwood timber, MDF.

The manufacturing process includes consolidation and release of materials, Manufacture and quality assurance, dispatch and customer services follow up of the delivered items.